The system adopts a master-slave distributed topology, that is, each system contains a motherboard and multiple slave boards. Daisy chain is used for data transmission and control between systems. The slave board is responsible for the sampling and equalization control of cell temperature and voltage. The main board is responsible for collecting the total voltage, total current, insulation, environment / cooling medium temperature, charging interface temperature, hvil and charging circuit status of the battery pack; Control the contactor, thermal management system and charge discharge control of battery system; The parameters of SOC, SOH, sof, actual capacity and internal resistance are calculated; Diagnose the fault of battery system and deal with it.

1. Overview

1.1 the master-slave distributed topology is adopted in Tianjin e-dingfeng BMS system, that is, each system includes a main board (BMU) and multiple slave boards (vtbu). The advanced isospi bus is used for data transmission and control between them. Vbtu is responsible for the sampling and equalization control of cell temperature and voltage. BMU is responsible for collecting the total voltage, total current, insulation, environment / cooling medium temperature, charging interface temperature, hvil and charging circuit status of the battery pack; Control the contactor, thermal management system and charging and discharging point control of battery system; The parameters of SOC, SOH, sof, actual capacity and internal resistance are calculated; Diagnose the fault of battery system and deal with it.

1.2 in order to ensure the high safety of the battery system, Tianjin yidingfeng BMS adopts the following high safety design:

(1) Adopt vehicle level requirements and development process.

(2) Dual CPU and a variety of redundant design of the security architecture to meet the functional security design of iso26262.

(3) Perfect fault diagnosis and protection mechanism, including: contactor adhesion detection, insulation, overvoltage, undervoltage, overcurrent, short circuit (internal and external), overheating, etc.

(4) Regularly wake up the battery safety monitoring, monitoring the status of the power battery system in the off state, to prevent the occurrence of dangerous events when the battery system is placed.

(5) In order to ensure the effectiveness and accuracy of the whole algorithm, in addition to the basic ampere hour accumulation and eigenvalue correction, the advanced SOC algorithm of battery internal resistance, cell internal temperature estimation, OCV real-time calculation and adaptive filtering is added to the algorithm; Advanced algorithms such as real-time correction of battery capacity ensure the accuracy of SOC, SOH, etc. of the cell, and can accurately estimate the allowable charging and discharging power of the battery and extend the service life of the cell.

2. Basic functions

2.1 main board function

(1) Dual core processor: Dual CPU and a variety of redundant design security architecture, to meet the functional security design of iso26262.

(2) Safety protection strategies: over charging protection, over discharge protection, high temperature protection, low temperature protection, current over-current protection and other 100 fault protection strategies.

(3) Accurate battery energy management: yidingfeng battery management system adopts model design, accurately estimates battery SOC based on second-order equivalent circuit, ensures that SOC is maintained in a reasonable range, prevents damage to battery due to overcharge or overdischarge, and accurately calculates energy or state of charge of energy storage battery.

(4) intelligent battery charging management: charge algorithm management based on battery equivalent circuit model, accurately estimate the state of the battery in the future 10s, adjust the charging current ahead of time, prevent the battery from being damaged by overcharge, prolong the battery life effectively, and ensure the charging efficiency.

(5) Reliable full condition balancing scheme: the full condition balancing scheme based on the battery equivalent circuit can balance the battery pack in the full condition and full period of the vehicle, greatly improve the battery balancing efficiency, effectively ensure the consistency of the monomer, and extend the battery life and range.

(6) Safe thermal management: thermal safety management, cooling control, heating and insulation control. BMS ensures the temperature difference of the battery cell, keeps the consistency of the cell, and extends the service life of the battery.

(7) Advanced contactor control strategy: can not rely on contactor feedback signal, only rely on logic judgment contactor adhesion, unable to close and other faults.

(8) battery internal resistance, internal temperature and OCV real-time calculation, timely predict the battery according to the battery state, adjust the charge and discharge current in advance, calibrate the SOC in time, and accurately estimate the SOH of the battery.

(9) Perfect fault protection strategy: accurately judge the possible battery faults, ensure the normal driving of the vehicle while meeting the user experience.

(10) Data monitoring and calibration based on CCP protocol.

(11) Insulation test meeting the requirements of national standard.

(12) The software development based on AUTOSAR architecture ensures the reliability and portability of the program and facilitates the upgrade of BMS development.

(13) Total voltage and insulation detection

2.2 sub board function

(1) Voltage acquisition: the maximum acquisition channel of each sub board is 12, and the voltage input range is 0~5VDC.

(2) Temperature acquisition: the maximum acquisition channel of each sub board is 3.

(3) Full working condition range Equalization: passive equalization, current<100mA.

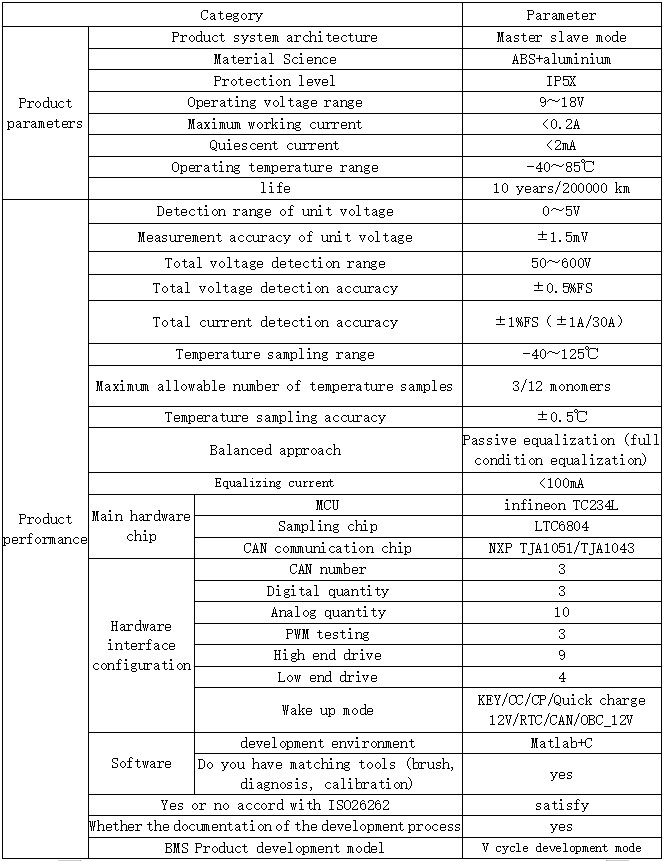

3.Technical parameters

公司地址:天津西青中北镇开源路6号

版权所有:天津易鼎丰动力科技有限公司 ICP备案:津ICP备2021002978号 公安备案:12011102000438